Product standards and specifications

1. Standards: GB1094, GB6450, GB / T10228, in accordance with DIN42523, IEC726

2. Capacity range: 30-16000kVA

3. Voltage level: 10kV, 35kV

4. Voltage regulation method: no excitation voltage regulation or on-load voltage regulation

5. Tap range: ± 5%, + 2x2 5%, ± 4x2 5%

6.Frequency: 50Hz or 60Hz

7. Number of phases: three-phase or single-phase

8. Connection group label: Yyn0, Dyn11 or other

9. Short-circuit impedance: standard impedance (see performance parameters)

10. When the altitude is less than 1000M and the ambient temperature is 400C lower than the above conditions, the corresponding adjustment should be made according to the standard.

11. Coil temperature rise: 100K

1 2. Refrigeration method: self cooling (AN) or air cooling (AF)

13. Shell protection level: IP00, IP20, IP23

14. Insulation class: Class F

15. Insulation level:

(1) 10KV grade products have a power frequency withstand voltage of 35KV and a lightning impulse voltage of 75KV

(2) 20KV class product power frequency withstand voltage 50KV, lightning strike voltage 125KV

(3) The power frequency withstand voltage of 35KV grade products is 70KV, and the lightning strike voltage is 170KV

Features

1. The high-voltage winding is made of enameled copper wire, and the low-voltage winding is made of copper foil. The high-voltage winding is filled with glass fiber felt. Under vacuum state, it is cast with imported epoxy resin without filler. After curing, it forms a solid whole with high mechanical strength, less partial discharge and high reliability.

2. Flame retardant, explosion-proof, non-polluting environment, environmental protection type, can be installed in the load base.

3. The coil does not absorb moisture, the iron core, and the clips can be operated in 100% relative humidity and other harsh environments after being processed by special processes. Intermittent operation does not require dehumidification treatment.

4. High level of short circuit resistance, lightning impact and strong overload capacity.

5. The resin insulation layer inside and outside the coil is thin, and the heat dissipation performance is good. An air cooling system (AF) can be configured for transformers of any protection level.

6. Low loss and high power saving effect. Economical operation and maintenance-free.

7. Small size, light weight, small floor space and easy installation.

8. As a new generation of dry-type transformers, SC (B) dry-type transformers are suitable for power supply in the following places; high-rise buildings, theaters, industrial and mining enterprises, offshore oil rigs, ships, subways, stations, airports, power plants , Residential quarters and high-rise buildings, etc .;

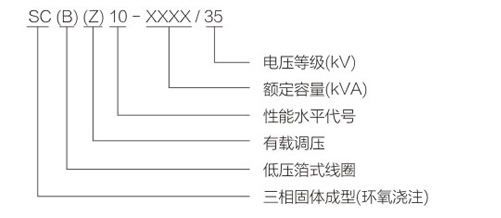

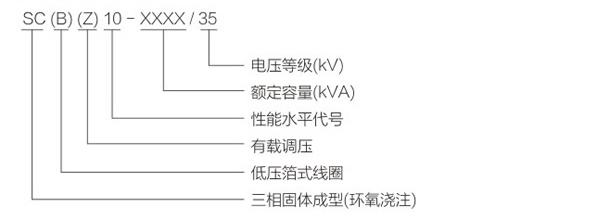

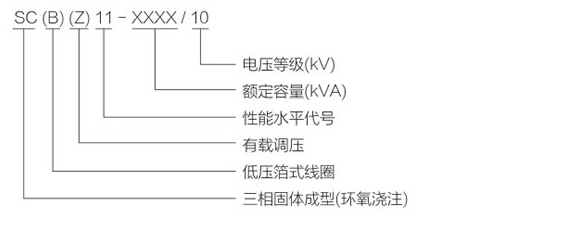

Model Meaning

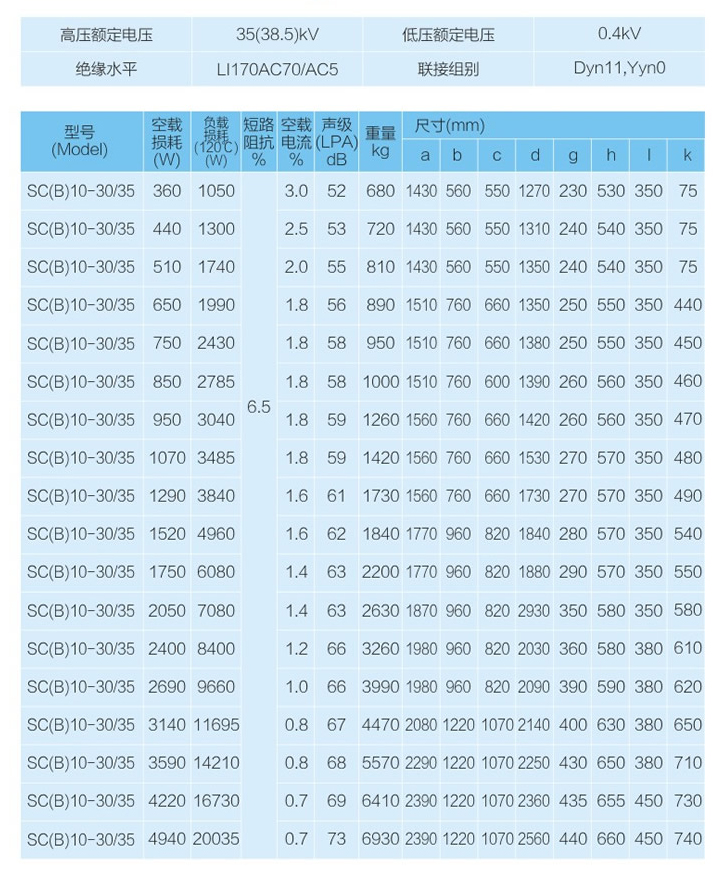

35KV grade dry cast transformer parameters

Model Meaning

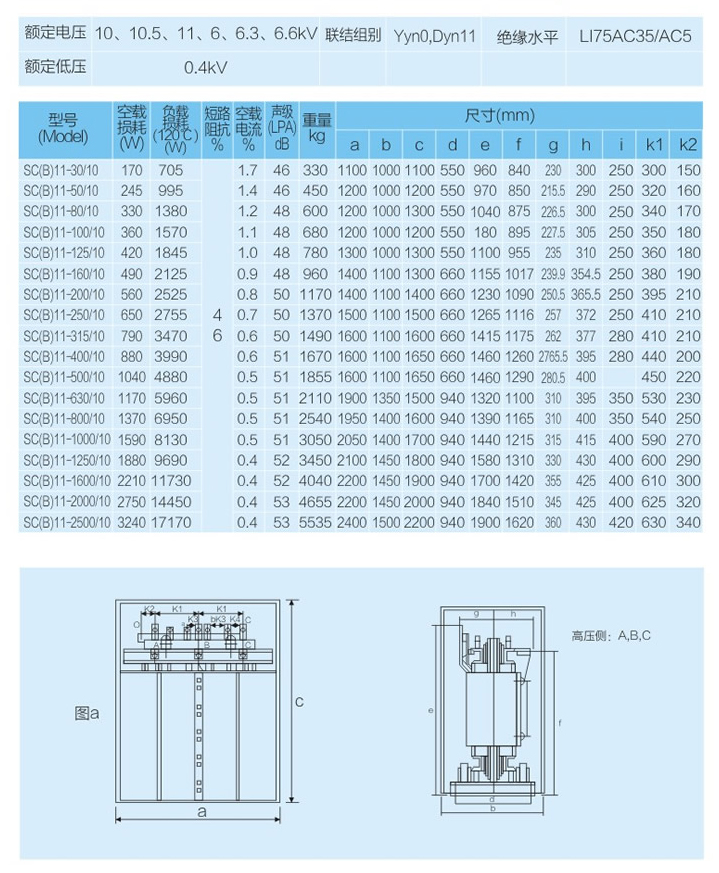

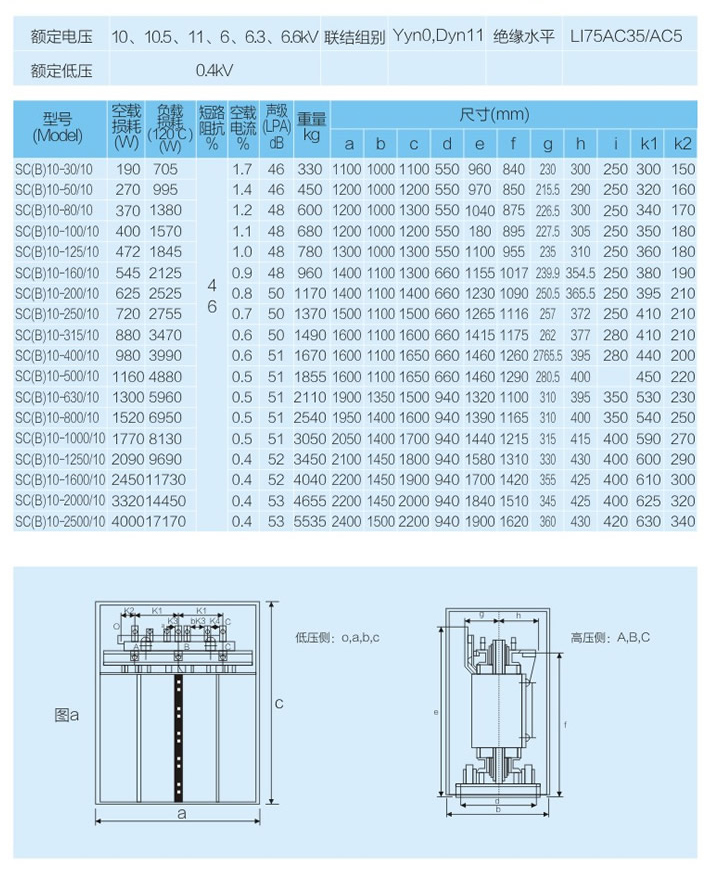

SC (B) 10 series 10kV level 30-2500kVA dry cast transformer parameters

Model Meaning

SC (B) 10 series 10kV level 30-2500kVA dry cast transformer parameters