Parameter

HC.KCS series fast capacitive non-contact switch is a power electronic product, you can use this product to connect the power capacitor load to the power grid. The crystal production is dedicated to the occasions where switch installation and control installation are required, and can realize the fast switching of the pure capacitance Wei series anti-step compensation system. Not only can symmetric three-phase current compensation be achieved, but also single-phase current stepwise compensation can be performed on the power grid.

-Protection level Ⅰ

-Control input: DC8-18V

-Distance to EN61010.2001 pollution and other waste IICAT II

-Supply voltage: Un 400V 50H2 / 60Hz

-Protection grade IP10

-Negative capacity: three-phase 60kVar (0.4kV / 70kVar (0.45kV);

Environmental characteristics: -Operating temperature -20C_ + 55C

Single-phase 13 5kVar (023 K) / 15kVar (0 25kV)

-Power consumption approximately 2W per amp

-Storage temperature -25C_ + 70C

-Creepage distance from control input to main circuit> 6mm

Installation position 1 straight or water early

-Rated voltage Un1 0%

-Harmonic voltage ThD max 5%

Once the response is <20mS

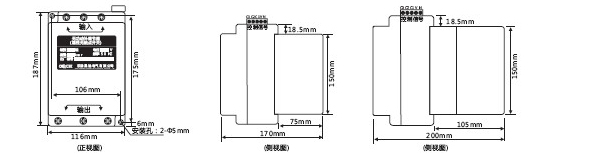

Dimensions: 220x115 x 205mm (H w D)

Continuous response is moderate <40mS

Weight: Nearly 3200g

Security item

Due to the design for wind rot. It must be ensured that the empty entrance is free. The radiator outlet cannot be covered. Pay attention to the separation from nearby components. For rated loads. The temperature difference between the air of the new crucian carp and the air pushed out will increase by 40C. Temperature-sensitive parts like cable ducts must be protected slowly with bushings.

It must work under the condition of serial disconnection equipment.

It must be applied on occasions that meet the conditions of use.

Even when KCS is dumped according to the regulations, the KCS failure cannot be avoided. In this case, the current and voltage of the load circuit will be affected. In the case of respect, Kog will have a rich situation: current interruption. Half-wave operation or continuous fear of volume loss. Therefore, in the project design stage, it is necessary to slowly prove the correctness of the design of slow-protection equipment.

Improper operation or wiring will lead to damage to the equipment load.

It must be connected with a cable gland with insulation protection.

The installation, maintenance and service of this equipment must be completed by a skilled electrician. When the KCS fast capacitive contactless switch is connected to the power supply system, the capacitive load (capacitor) will be charged to the peak of the grid voltage. This means that even when the switch is disconnected, the load is still live and still connected to the grid. Therefore, when installation and maintenance work is carried out, it must be disconnected from the grid in any case. Otherwise there is danger to life!

After disconnection from the grid, there is still residual voltage in the capacitive load. Before installation and maintenance work, check whether the capacitor is live. The discharge time of the capacitor must be considered.

Discharge resistance has been added to the switch, no need to connect the discharge device.

When a reactor is connected in series, the complexity of the power grid must be fully considered, especially when harmonic elimination of a fixed order harmonic signal may amplify the harmonic signal of other orders.It is recommended to use the Work compensation controller, otherwise it will damage the switch due to the effect of charge conduction.

Application

HC.KCS is particularly suitable for applications where the frequency and reactive power change rapidly. Compared with traditional technology, the advantages of KCS are:

-Fast switching speed

-Little pollution to the system when switching

-No wear parts when switching

-Long service life and unlimited operating frequency.

Application areas:

-Crane equipment

-Elevator

-Welding equipment

-Molding

-Wind turbine

HC.KCS can work with reactive power controllers, programmable controllers, computer systems and process control units.

Installation

HC.KCS can be installed horizontally or straight. Due to forced heat dissipation, all productive warm air is almost discharged in one direction. If there are temperature-sensitive components in the system, like cable ducts, they must be protected with bushings. Distance: Fan side:> 50mm Cooling outlet:> 150mm

If installed vertically, hot air must be discharged from above. Note: When installing vertically, foreign objects should be prevented from falling into the radiator and causing damage to the fan, so the radiator must be covered with a protective plate or the like during installation, and the protective plate should be removed before testing and operation.

Wiring

When connecting with an insulated cable connector (8mm ring) to the load circuit, the terminal connector must be tightened with 5.5-6Nm, and the cable connector must be completely perpendicular to the conduction. When placing the wiring, it should be ensured that the wiring will not heat up due to the radiator. A circuit breaker must be designed to protect the semiconductor device, and the size of the circuit breaker should be designed according to the connected capacitive load. For the compensation equipment with reactor protection, the non-contact switch must be connected in series in front of the inductor and capacitor.

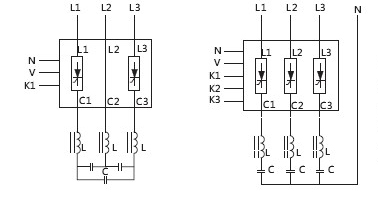

1. Three-phase symmetrical compensation wiring diagram KCS1A:

2. Three-phase separately compensated wiring diagram KCS3F:

3. Description of secondary terminals

N: transformer neutral (neutral)

K1: The common complement type is a three-phase trigger terminal: the split complement type is the LI phase Dufa terminal (active low level)

K2: L2 phase trigger terminal of subcomplement type (active low level)

K3: L3 phase trigger terminal of subcomplement type (active low level)

V: common end of control signal